How Clean are My Fuel Storage Tanks?

Advanced Fuel Services (AFS) is a division of Frost Oil that offers a complete line of services designed to ensure the quality and integrity of your fuel. Utilizing trained technicians and state of the art technology, AFS can diagnose, treat and solve a wide range of problems that are a threat to today’s motor fuels.

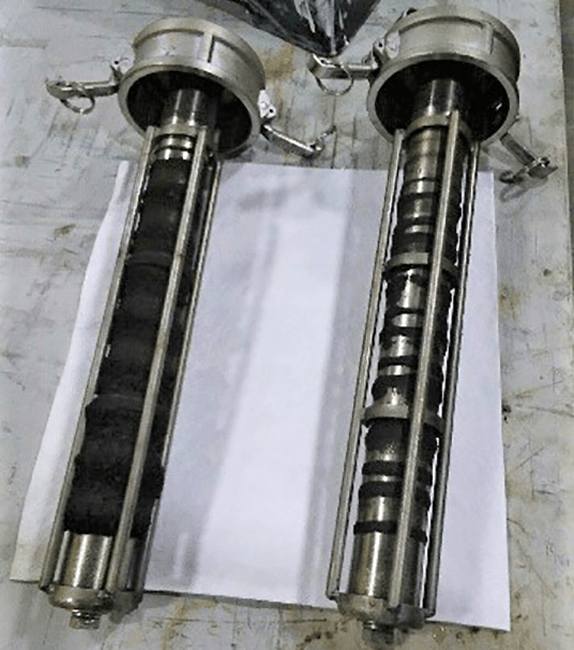

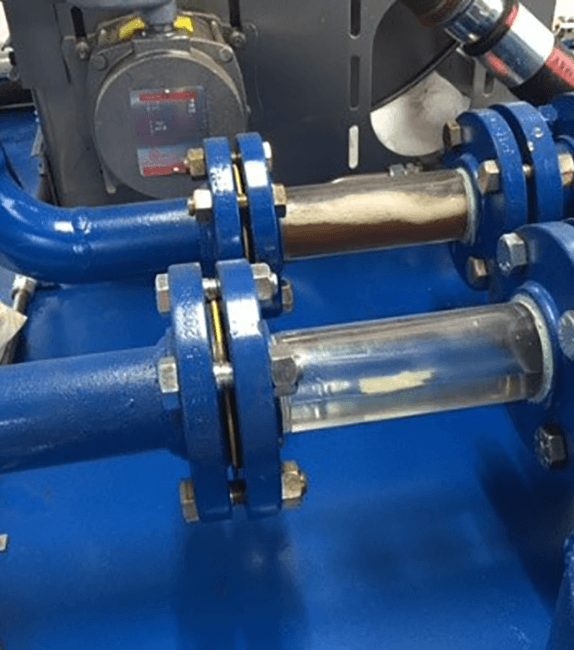

AFS is one of the few companies in our marketing area that offers fuel polishing, which is the technical cleaning process used to filter and remove contaminants from stored fuel. In addition, we recommend and implement programs designed to prevent future problems through the use of fuel analysis, tank cleaning and additive programs.